DESIGN & MAINTENANCE

Process

01

Preliminary Design

Establishment of installation scale, timing, budget planning

Investigation of regulations, ordinances, and design guidelines

Calculation of anticipated energy self-sufficiency rate

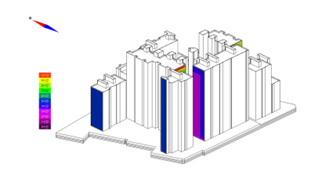

Planning of BIPV installation scope

02

Detailed Design

Design of building layout, orientation, form

Finalization of building design

Compilation of related documents (architectural, electrical design)

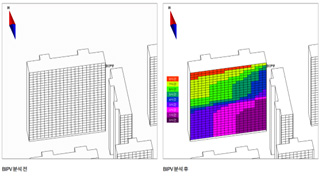

BIPV shading analysis and detailed design of installation scale

03

Installation

Implementation of building according to design drawings

Establishment of process, lifting, installation, safety plans

Manufacturing and quality control of BIPV modules

04

Maintenance

Building maintenance

Maintenance of facility safety

Conducting routine and regular inspections

Main Issue

Preliminary Design

- Review relevant laws, support ordinances, and design guidelines.

- Calculate the mandatory ratio (self-sufficiency rate) for the project.

- Establish a renewable energy installation plan based on calculations.

Site Conditions Analysis [Installation Conditions Review]

Guidelines related to the support of renewable energy facilities

1. Module Installation Capacity

Possible to install up to 110% of the design capacity

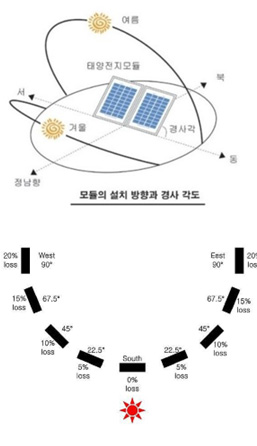

2. Installation State

1) Must be installed within 45 degrees to the east or west of true south (60 degrees for facilities subject to supply certification).

2) For solar facilities (BAPV or BIPV type) installed parallel to existing building roofs or walls, installation can be within 90 degrees to the east or west of true south.

3) Modules must receive at least 5 hours of sunlight per day, based on spring (March-May) and autumn (September-November) standards.

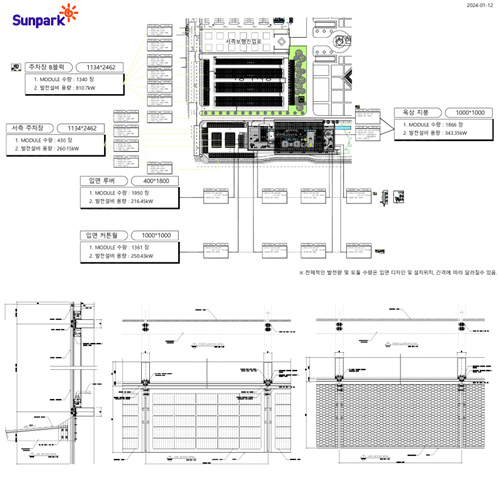

Construction Documents

- Building Layout and Orientation Planning

- BIPV Power Generation and Shading Review

- BIPV Facade Layout and Detailed Design

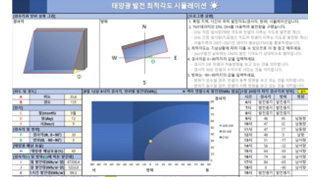

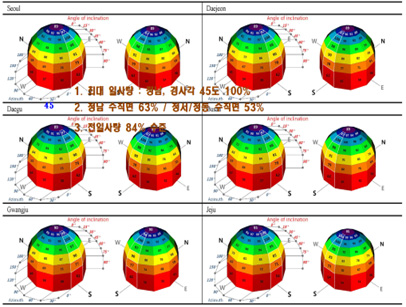

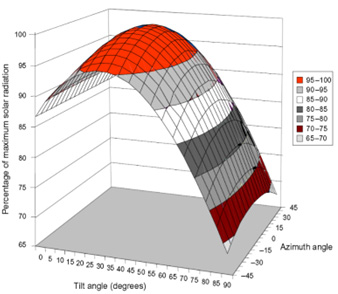

Site Conditions Analysis [Generation Review by Installation Angle]

[At a 45° inclination, 100% compared to horizontal 90%, vertical 75%]

(Based on true south orientation)

Annual Total Solar Irradiance Ratio by BIPV Installation Inclination and Orientation Angle

(Based on Korean Solar Energy Society TRY weather data for six regions in Korea)

[At a 45° inclination, 100% compared to horizontal 90%, vertical 75%]

(Based on true south orientation)

Annual Total Solar Irradiance Ratio by BIPV Installation Inclination and Orientation Angle

(Average values for six regions in Korea)

Construction

| Construction Plan | Hardware Construction | Module Manufacturing | Material Delivery and Unloading | BIPV Construction In Progress | BIPV Construction Completion | Electrical & Monitoring |

|---|---|---|---|---|---|---|

| Process Planning Lifting Plan Equipment Plan Installation Plan Safety Plan Electrical Construction Plan |

Baseline Work Bringing in hardware Lifting hardware Installation of lower hardware |

Whole cell inspection Tabbing & Stringing Lay-up Glass Cleaning Lamination Triming J-box Fixing Simulation Packaging |

Material Release Material Delivery and Unloading Material Sorting (by installation surface, capacity) Material Lifting |

Module Inspection BIPV Module Installation Module Connection Work |

Inspection See what’s left |

Inverters Delivery & Inspection Construction Site Lifting Electrical Conduit Installation Commissioning |

Installation

- Establish process, lifting, installation, and safety plans.

- Manufacture and quality control of BIPV modules.

- Installation and quality control of BIPV modules.

- Implementation of buildings according to design drawings.

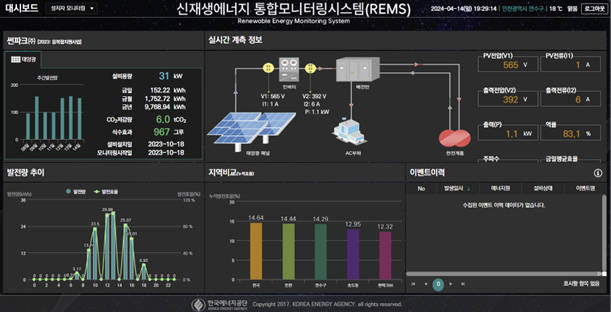

Maintenance

- Conduct routine, regular, and safety inspections.

- Monitor operation through system checks.

- Verify daily, monthly, and annual power generation.

- Replace BIPV modules due to failures, damages, or contamination.